Mesh/Elastomer Combinations

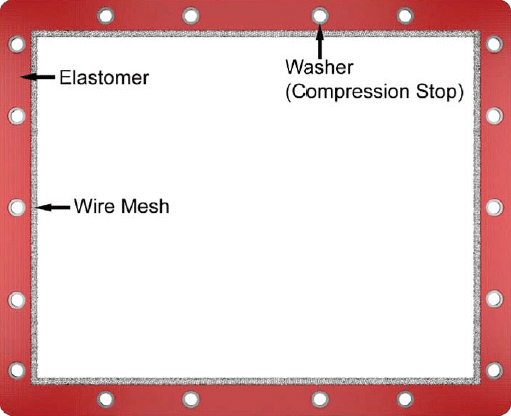

SAS SEALTRON Materials include wire mesh and elastomer combinations as well. This material is ideally suited for situations where joint unevenness is a concern, due to its ease of compressibility. Typical applications for wire mesh and elastomer combinations are enclosure gaskets which require both an environmental seal and EMI shielding. Additionally, for applications which require both low closure force with high deflection where sponge elastomers are used it is recommended to add compression stops to the gasket as shown in the last diagram of this section to prevent over compression. These can be supplied bonded in the gasket as washers, as illustrated or as solid metal “plugs”.

These are available in various different metal and elastomer combinations.

An adhesive strip can also be added to the elastomer for ease of assembly.

The following part number system classifies the material as being part of our Wire Mesh / Elastomer Combinations line.

PN | Elastomer (Specification) | Wire (Specification) |

|---|---|---|

4110 | Closed Cell Neoprene Medium (MIL-R-6130 Type 2 Grade A Medium) Closed Cell Neoprene Medium (ASTM-D-6576 Type 2 Grade A Medium) | .0045” Dia Monel Wire (QQ-N-281) |

4111 | Closed Cell Neoprene Soft (MIL-R-6130 Type 2 Grade A Soft) Closed Cell Neoprene Soft (ASTM-D-6576 Type 2 Grade A Soft) | .0045” Dia Monel Wire (QQ-N-281) |

4112 | Closed Cell Neoprene Firm (MIL-R-6130 Type 2 Grade A Firm) Closed Cell Neoprene Firm (ASTM-D-6576 Type 2 Grade A Firm) | .0045” Dia Monel Wire (QQ-N-281) |

4120 | Closed Cell Neoprene Medium (MIL-R-6130 Type 2 Grade A Medium) Closed Cell Neoprene Medium (ASTM-D-6576 Type 2 Grade A Medium) | .0045” Dia SnCuFe (ASTM-B-520) |

4121 | Closed Cell Neoprene Soft (MIL-R-6130 Type 2 Grade A Soft) Closed Cell Neoprene Soft (ASTM-D-6576 Type 2 Grade A Soft) | .0045” Dia SnCuFe (ASTM-B-520) |

4122 | Closed Cell Neoprene Firm (MIL-R-6130 Type 2 Grade A Firm) Closed Cell Neoprene Firm (ASTM-D-6576 Type 2 Grade A Firm) | .0045” Dia SnCuFe (ASTM-B-520) |

4130 | Closed Cell Neoprene Medium (MIL-R-6130 Type 2 Grade A Medium) Closed Cell Neoprene Medium (ASTM-D-6576 Type 2 Grade A Medium) | .005” Dia Alloy 5056 |

4131 | Closed Cell Neoprene Soft (MIL-R-6130 Type 2 Grade A Soft) Closed Cell Neoprene Soft (ASTM-D-6576 Type 2 Grade A Soft) | .005” Dia Alloy 5056 |

4132 | Closed Cell Neoprene Firm (MIL-R-6130 Type 2 Grade A Firm) Closed Cell Neoprene Firm (ASTM-D-6576 Type 2 Grade A Firm) | .005” Dia Alloy 5056 |

4140 | Closed Cell Neoprene Medium (MIL-R-6130 Type 2 Grade A Medium) Closed Cell Neoprene Medium (ASTM-D-6576 Type 2 Grade A Medium) | .0045” Dia SnPhBronze (ASTM-B-105) |

4141 | Closed Cell Neoprene Soft (MIL-R-6130 Type 2 Grade A Soft) Closed Cell Neoprene Soft (ASTM-D-6576 Type 2 Grade A Soft) | .0045” Dia SnPhBronze (ASTM-B-105) |

4142 | Closed Cell Neoprene Firm (MIL-R-6130 Type 2 Grade A Firm) Closed Cell Neoprene Firm (ASTM-D-6576 Type 2 Grade A Firm) | .0045” Dia SnPhBronze (ASTM-B-105) |

4210 | Closed Cell Silicone Medium (MIL-R-6130 Type 2 Grade B/C Medium) Closed Cell Silicone Medium (ASTM-D-6576 Type 2 Grade B/C Medium) Closed Cell Silicone Medium (AMS3195) | .0045” Dia Monel Wire (QQ-N-281) |

4211 | Closed Cell Silicone Soft (MIL-R-6130 Type 2 Grade B/C Soft) Closed Cell Silicone Soft (ASTM-D-6576 Type 2 Grade B/C Soft) | .0045” Dia Monel Wire (QQ-N-281) |

4212 | Closed Cell Silicone Firm (MIL-R-6130 Type 2 Grade B/C Firm) Closed Cell Silicone Firm (ASTM-D-6576 Type 2 Grade B/C Firm) Closed Cell Silicone Firm (AMS3196) | .0045” Dia Monel Wire (QQ-N-281) |

4220 | Closed Cell Silicone Medium (MIL-R-6130 Type 2 Grade B/C Medium) Closed Cell Silicone Medium (ASTM-D-6576 Type 2 Grade B/C Medium) Closed Cell Silicone Medium (AMS3195) | .0045” Dia SnCuFe (ASTM-B-520) |

4221 | Closed Cell Silicone Soft (MIL-R-6130 Type 2 Grade B/C Soft) Closed Cell Silicone Soft (ASTM-D-6576 Type 2 Grade B/C Soft) | .0045” Dia SnCuFe (ASTM-B-520) |

4222 | Closed Cell Silicone Firm (MIL-R-6130 Type 2 Grade B/C Firm) Closed Cell Silicone Firm (ASTM-D-6576 Type 2 Grade B/C Firm) Closed Cell Silicone Firm (AMS3196) | .0045” Dia SnCuFe (ASTM-B-520) |

4230 | Closed Cell Silicone Medium (MIL-R-6130 Type 2 Grade B/C Medium) Closed Cell Silicone Medium (ASTM-D-6576 Type 2 Grade B/C Medium) Closed Cell Silicone Medium (AMS3195) | .005” Dia Alloy 5056 |

4231 | Closed Cell Silicone Soft (MIL-R-6130 Type 2 Grade B/C Soft) Closed Cell Silicone Soft (ASTM-D-6576 Type 2 Grade B/C Soft) | .005” Dia Alloy 5056 |

4232 | Closed Cell Silicone Firm (MIL-R-6130 Type 2 Grade B/C Firm) Closed Cell Silicone Firm (ASTM-D-6576 Type 2 Grade B/C Firm) Closed Cell Silicone Firm (AMS3196) | .005” Dia Alloy 5056 |

4240 | Closed Cell Silicone Medium (MIL-R-6130 Type 2 Grade B/C Medium) Closed Cell Silicone Medium (ASTM-D-6576 Type 2 Grade B/C Medium) Closed Cell Silicone Medium (AMS3195) | .0045” Dia SnPhBronze (ASTM-B-105) |

4241 | Closed Cell Silicone Soft (MIL-R-6130 Type 2 Grade B/C Soft) Closed Cell Silicone Soft (ASTM-D-6576 Type 2 Grade B/C Soft) | .0045” Dia SnPhBronze (ASTM-B-105) |

4242 | Closed Cell Silicone Firm (MIL-R-6130 Type 2 Grade B/C Firm) Closed Cell Silicone Firm (ASTM-D-6576 Type 2 Grade B/C Firm) Closed Cell Silicone Firm (AMS3196) | .0045” Dia SnPhBronze (ASTM-B-105) |

4243 | Medium Cellular Silicone (AMS3195) | .0045” Dia SnPhBronze (ASTM-B-105) |

4314 | Solid Neoprene, 40 Durometer (MIL-R-6855 Class 2 Grade 40) Solid Neoprene, 40 Durometer (AMS-R-6855 Class 2 Grade 40) | .0045” Dia Monel Wire (QQ-N-281) |

4324 | Solid Neoprene, 40 Durometer (MIL-R-6855 Class 2 Grade 40) Solid Neoprene, 40 Durometer (AMS-R-6855 Class 2 Grade 40) | .0045” Dia SnCuFe (ASTM-B-520) |

4334 | Solid Neoprene, 40 Durometer (MIL-R-6855 Class 2 Grade 40) Solid Neoprene, 40 Durometer (AMS-R-6855 Class 2 Grade 40) | .005” Dia Alloy 5056 |

4344 | Solid Neoprene, 40 Durometer (MIL-R-6855 Class 2 Grade 40) Solid Neoprene, 40 Durometer (AMS-R-6855 Class 2 Grade 40) | .0045” Dia SnPhBronze (ASTM-B-105) |

4413 | Solid Silicone, 30 Durometer (ZZ-R-765 Class 3A Grade 40) Solid Silicone, 30 Durometer (A-A-59588 Class 3A Grade 40) | .0045” Dia Monel Wire (QQ-N-281) |

4414 | Solid Silicone, 40 Durometer (ZZ-R-765 Class 2B Grade 40) Solid Silicone, 40 Durometer (A-A-59588 Class 2B Grade 40) Solid Silicone, 40 Durometer (AMS3301) | .0045” Dia Monel Wire (QQ-N-281) |

4423 | Solid Silicone, 30 Durometer (ZZ-R-765 Class 3A Grade 40) Solid Silicone, 30 Durometer (A-A-59588 Class 3A Grade 40) | .0045” Dia SnCuFe (ASTM-B-520) |

4424 | Solid Silicone, 40 Durometer (ZZ-R-765 Class 2B Grade 40) Solid Silicone, 40 Durometer (A-A-59588 Class 2B Grade 40) Solid Silicone, 40 Durometer (AMS3301) | .0045” Dia SnCuFe (ASTM-B-520) |

4433 | Solid Silicone, 30 Durometer (ZZ-R-765 Class 3A Grade 40) Solid Silicone, 30 Durometer (A-A-59588 Class 3A Grade 40) | .005” Dia Alloy 5056 |

4434 | Solid Silicone, 40 Durometer (ZZ-R-765 Class 2B Grade 40) Solid Silicone, 40 Durometer (A-A-59588 Class 2B Grade 40) Solid Silicone, 40 Durometer (AMS3301) | .005” Dia Alloy 5056 |

4443 | Solid Silicone, 30 Durometer (ZZ-R-765 Class 3A Grade 40) Solid Silicone, 30 Durometer (A-A-59588 Class 3A Grade 40) | .0045” Dia SnPhBronze (ASTM-B-105) |

4444 | Solid Silicone, 40 Durometer (ZZ-R-765 Class 2B Grade 40) Solid Silicone, 40 Durometer (A-A-59588 Class 2B Grade 40) Solid Silicone, 40 Durometer (AMS3301) | .0045” Dia SnPhBronze (ASTM-B-105) |

4510 | Closed Cell Fluorosilicone Medium (AMS3323) | .0045” Dia Monel Wire (QQ-N-281) |

4520 | Closed Cell Fluorosilicone Medium (AMS3323) | .0045” Dia SnCuFe (ASTM-B-520) |

4530 | Closed Cell Fluorosilicone Medium (AMS3323) | .005” Dia Alloy 5056 |

4540 | Closed Cell Fluorosilicone Medium (AMS3323) | .0045” Dia SnPhBronze (ASTM-B-105) |

4514 | Solid Fluorosilicone, 40 Durometer (MIL-DTL-25988 Type 2 Class 1 Grade 40) | .0045” Dia Monel Wire (QQ-N-281) |

4524 | Solid Fluorosilicone, 40 Durometer (MIL-DTL-25988 Type 2 Class 1 Grade 40) | .0045” Dia SnCuFe (ASTM-B-520) |

4534 | Solid Fluorosilicone, 40 Durometer (MIL-DTL-25988 Type 2 Class 1 Grade 40) | .005” Dia Alloy 5056 |

4544 | Solid Fluorosilicone, 40 Durometer (MIL-DTL-25988 Type 2 Class 1 Grade 40) | .0045” Dia SnPhBronze (ASTM-B-105) |

Additionally the following table can be used to select a part number from the figures below. See the footnotes below the table for full ordering information including how to add PSA to the elastomer.

PN | Height | Elastomer Width | Wire Mesh Width |  |

|---|---|---|---|---|

4xxx-x001-NA | .062” | .250” | .125” | |

4xxx-x002-NA | .062” | .375” | .125” | |

4xxx-x003-NA | .062” | .500” | .125” | |

4xxx-x004-NA | .062” | .625” | .125” | |

4xxx-x005-NA | .093” | .250” | .125” | |

4xxx-x006-NA | .093” | .375” | .125” | |

4xxx-x007-NA | .093” | .500” | .125” | |

4xxx-x008-NA | .093” | .625” | .125” | |

4xxx-x009-NA | .093” | .750” | .125” | |

4xxx-x010-NA | .125” | .125” | .125” | |

4xxx-x011-NA | .125” | .187” | .125” | |

4xxx-x012-NA | .125” | .187” | .187” | |

4xxx-x013-NA | .125” | .250” | .125” | |

4xxx-x014-NA | .125” | .250” | .250” | |

4xxx-x015-NA | .125” | .375” | .125” | |

4xxx-x016-NA | .125” | .500” | .125” | |

4xxx-x017-NA | .125” | .500” | .250” | |

4xxx-x018-NA | .125” | .500” | .500” | |

4xxx-x019-NA | .125” | .625” | .125” | |

4xxx-x020-NA | .125” | .750” | .125” | |

4xxx-x021-NA | .125” | .750” | .250” | |

4xxx-x022-NA | .187” | .125” | .125” | |

4xxx-x023-NA | .187” | .187” | .125” | |

4xxx-x024-NA | .187” | .250” | .125” | |

4xxx-x025-NA | .187” | .250” | .250” | |

4xxx-x026-NA | .187” | .375” | .125” | |

4xxx-x027-NA | .187” | .500” | .125” | |

4xxx-x028-NA | .187” | .625” | .125” | |

4xxx-x029-NA | .187” | .625” | .250” | |

4xxx-x030-NA | .187” | .750” | .250” | |

4xxx-x031-NA | .250” | .125” | .125” | |

4xxx-x032-NA | .250” | .250” | .125” | |

4xxx-x033-NA | .250” | .375” | .125” | |

4xxx-x034-NA | .250” | .500” | .125” | |

4xxx-x035-NA | .250” | .625” | .125” | |

4xxx-x036-NA | .250” | .750” | .125” | |

4xxx-x037-NA | .250” | .750” | .250” | |

4xxx-x038-NA | .125” | .046” | .046” |

Replace the first x in the second series of the part number (e.g. 4xxx-x) with a 0 for Figure 1 configuration and a 9 for Figure 2 configuration.

Additionally, for solid elastomers, it is recommended the wire be .031” higher then the elastomer. To order with an additional .031” height on the elastomer replace the first x in the second series of the part number (e.g. 4xxx-x) with a 3 for Figure 1 configuration adding .031” to the wire or a 7 for Figure 2 configuration adding .031” to the wire.

Further, for solid elastomers where a 5 degree draft is desired on each side of the elastomer, where the represented width is the widest part where the elastomer meets the mesh, replace the first x in the second series of the part number (e.g. 4xxx-x) with a 5 for Figure 1 configuration only.

Replace 4xxx with the appropriate Material PN as illustrated in the table above this table to complete the part number. To add PSA backing to the elastomer portion of the Wire Mesh Elastomer Combination replace – NA with – A1.

The following chart shows typical performance characteristics of the wire mesh.

Monel | SnCuFe | Alloy 5056 | SnPhBronze | ||

|---|---|---|---|---|---|

Shielding Effectiveness | 100 KHz | 45 | 50 | 40 | 65 |

10 MHz | 115 | 115 | 100 | 120 | |

500 KHz | 110 | 110 | 90 | 110 | |

1 GHz | 95 | 95 | 80 | 95 | |

Closure Force (min) | psi | 10 | 10 | 10 | 10 |

Compression Set (40 min psi) | % | 7 | 9 | 12 | 9 |

In addition these Wire Mesh Elastomer Combinations can also be supplied as finished gaskets to any design. They can be designed using any of the combinations above along with compression stops as desired. A brief example of what can be done is shown below.